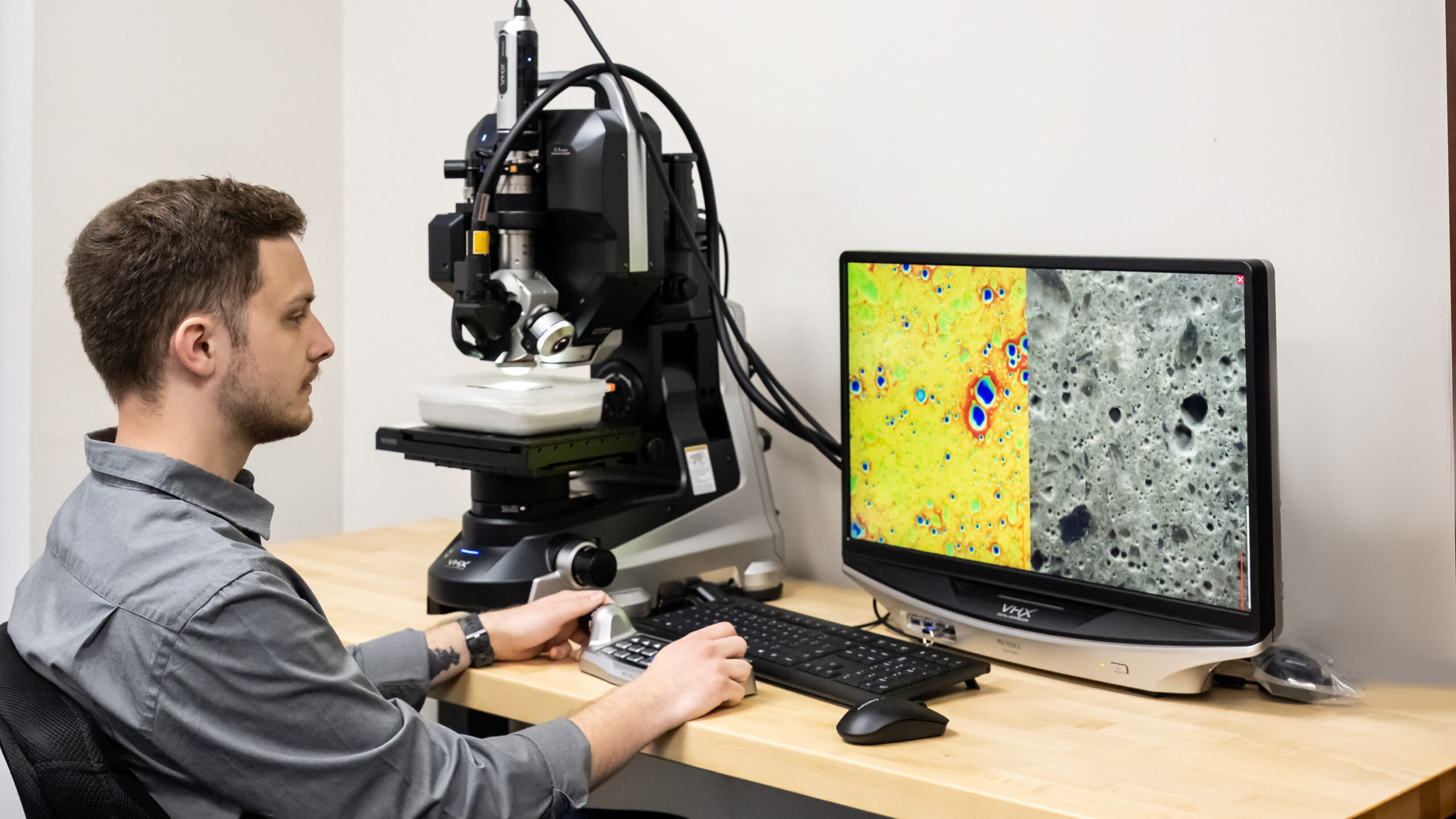

Petrography

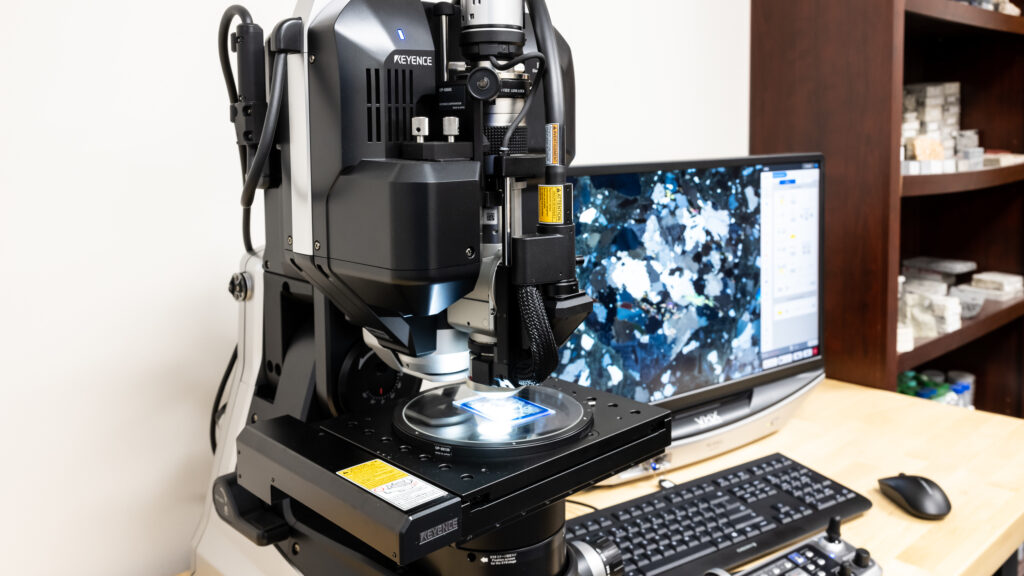

Concrete Petrography – ASTM C856 is the standard practice for petrographic examination of hardened concrete.

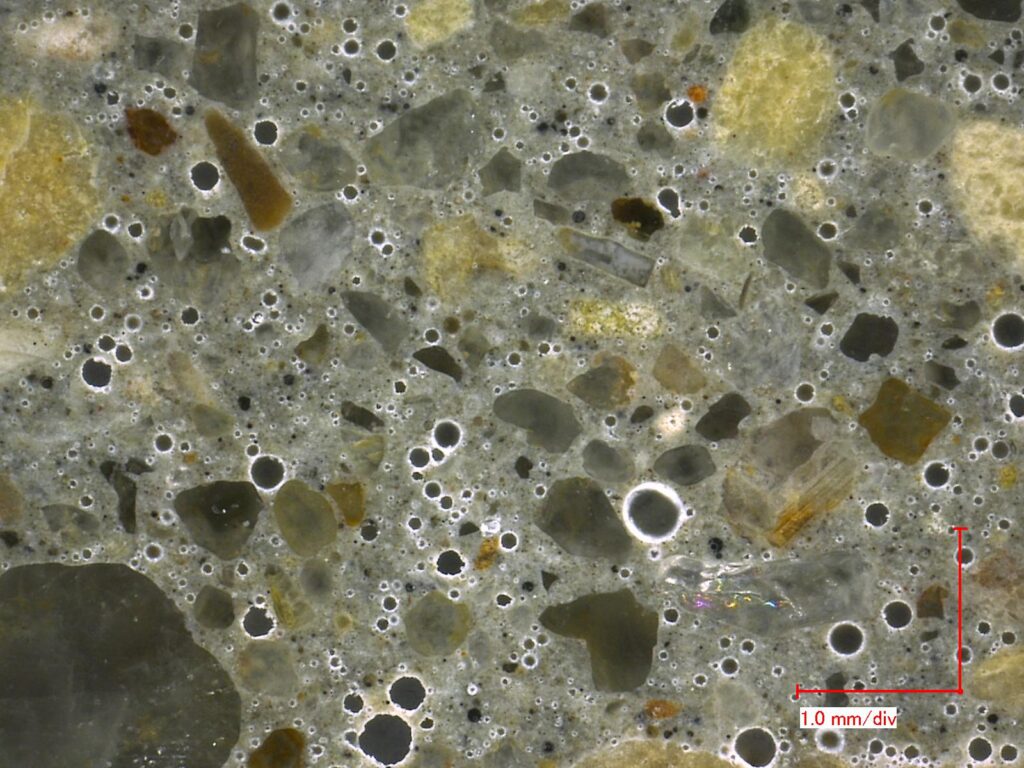

Petrographic examination reveals key characteristics of hardened concrete. Samples, typically prepared from core extractions or test cylinders, are cut, ground, and polished. These prepared surfaces are then analyzed under a microscope, using magnifications from 10x to 60x for lapped sections and up to 400x for thin sections. Examinations follow ASTM C856 guidelines to assess a range of important concrete properties, like:

- Water to Cement Ratio

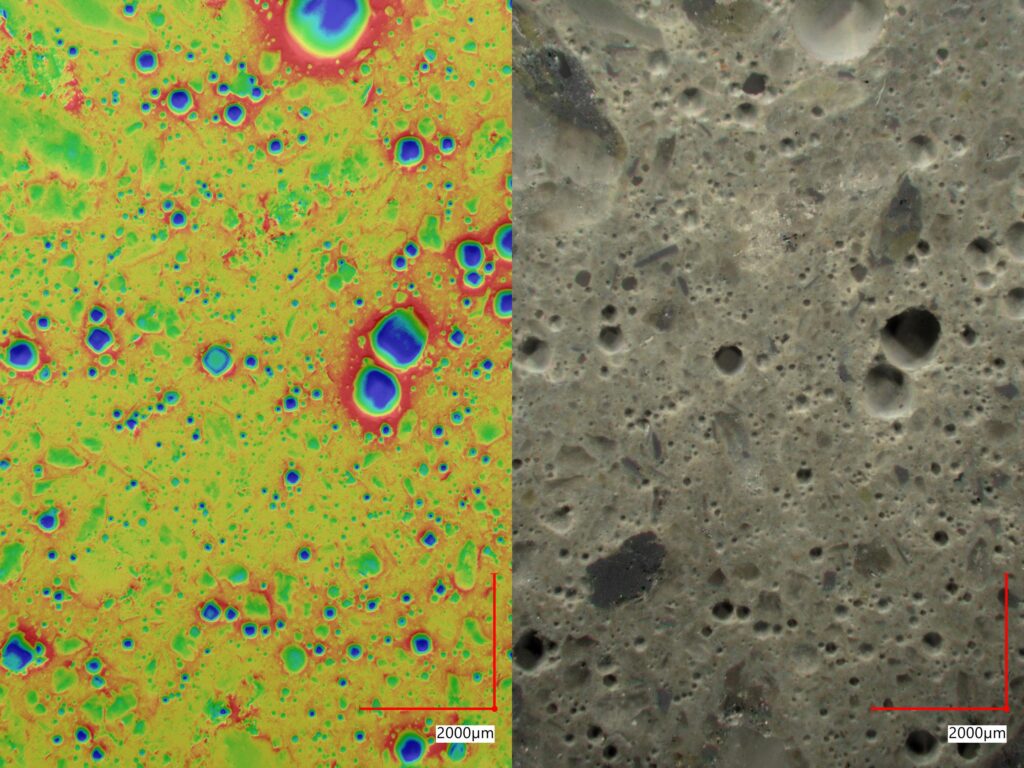

- Air Content

- Chemical Attack

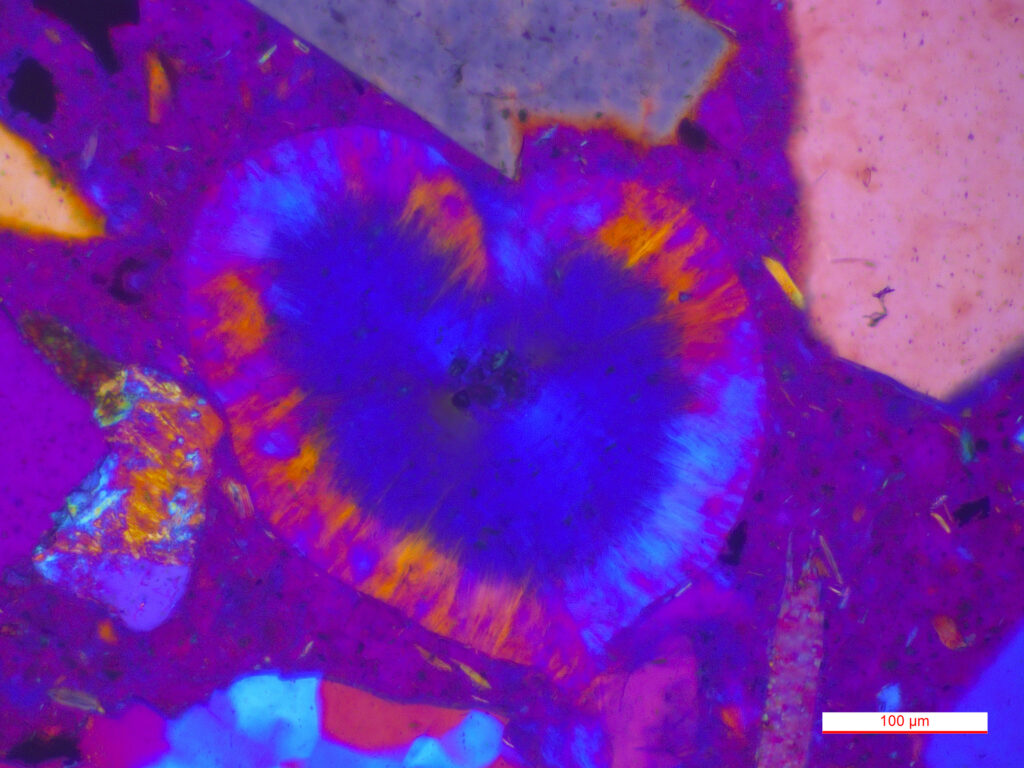

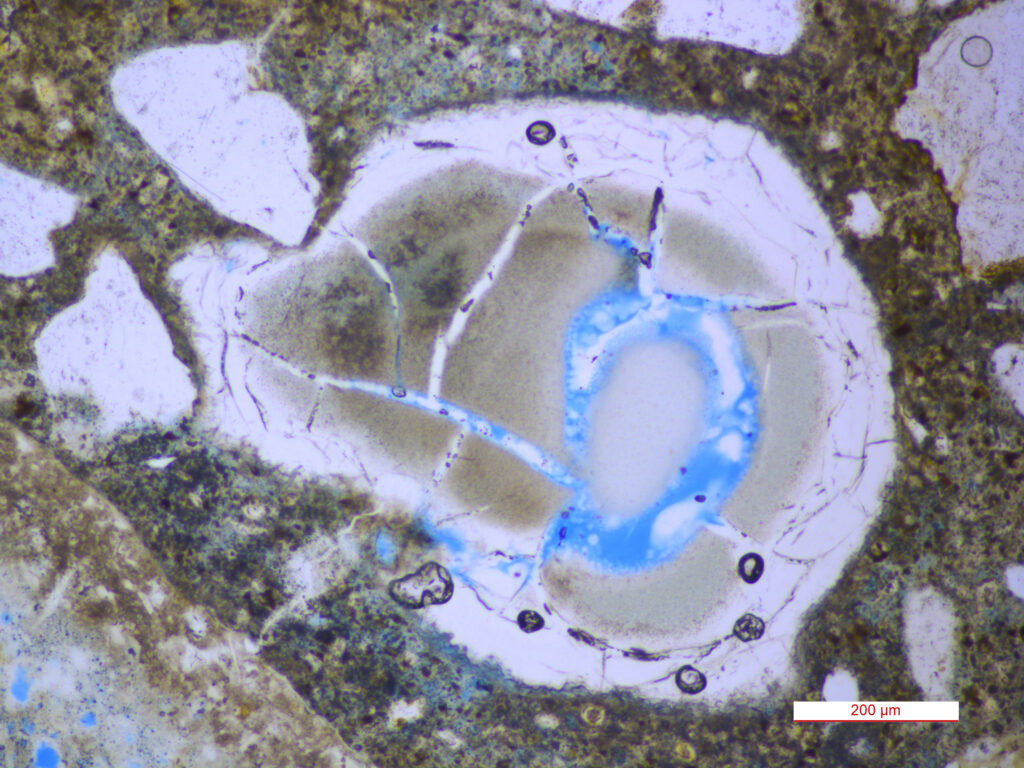

- Alkali Silica Reactions (ASR)

- Freeze Thaw Damage

- Paste Carbonation

- Low Strength Concrete

- Coating Failure or Delamination

- Moisture Vapor Issue

- Improper Curing

- Consolidation

- Porosity of Paste

- Corrosion of Reinforcing Steel

- Fire Damage

- Cause of Cracking

- Sulfate Attack

- Improper Finishing

- Seismic Damage

- Supplemental Cementitious Material (Fly Ash, Slag, etc.)

- Aggregate Mineralogy

- Aggregate Segregation

- Topping Verification

- Water Content

Key findings can answer questions like:

- Why are my compressive strength values less than the design?

- How do I know the provided concrete matches the mix design?

- Was too much air entrainment added to the concrete?

- Why did the surface of the concrete flake off?

- What is the existing condition of the concrete in my 40 year old building?

- Why is my concrete a completely different shade of gray in some areas?

- Is the existing surface of my concrete slab capable of accepting a coating?

- Why are there so many cracks in my slab?

- Is it time to remove and replace the existing concrete slab?

To learn more about our petrographic concrete testing contact an expert today.