Laboratory Testing

Laboratory Testing for Construction Materials

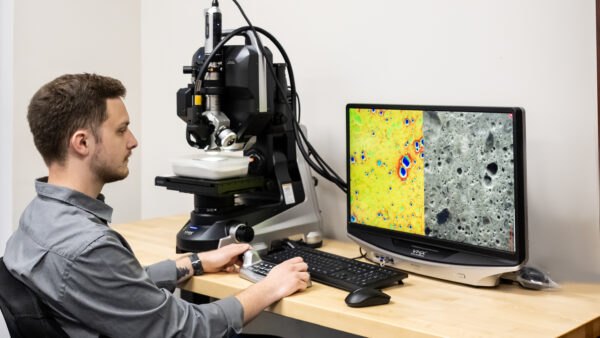

We truly are experts – we perform materials testing that few laboratories are accredited for or proficient in. Our accredited laboratory works closely with ASTM and other regulatory agencies in the development of test methods, testing guidelines, and specifications. Our employees are active members in ACI, ASTM, ICRI, FRCA, ASCE and SWRI and several are current or past committee members, committee chairs, board members, and presidents of local and national chapters.

Our state-of-the-art laboratory leverages industry-leading technologies to deploy advanced testing for our Consulting and Field Inspection Services and our clientele. We work with building owners, contractors, law firms, concrete producers, material manufacturers, engineering firms, government agencies, facility owners, and suppliers.

Contact an expert today to discuss your testing requirements.

From concrete testing to petrographic analysis, our laboratory can test and provide forensic examination for a wide range of materials.

Our materials testing laboratory offers a wide range of standard and custom tests to ensure your construction projects meet expectations, specifications, and regulatory requirements. Below is a list of common materials we test.

- Absorption

- Bond in Direct Tension

- Bond Strength Flexural

- Bond Strength Shear

- Color

- Compress Shear

- Compressive Strength

- Compressive Yield

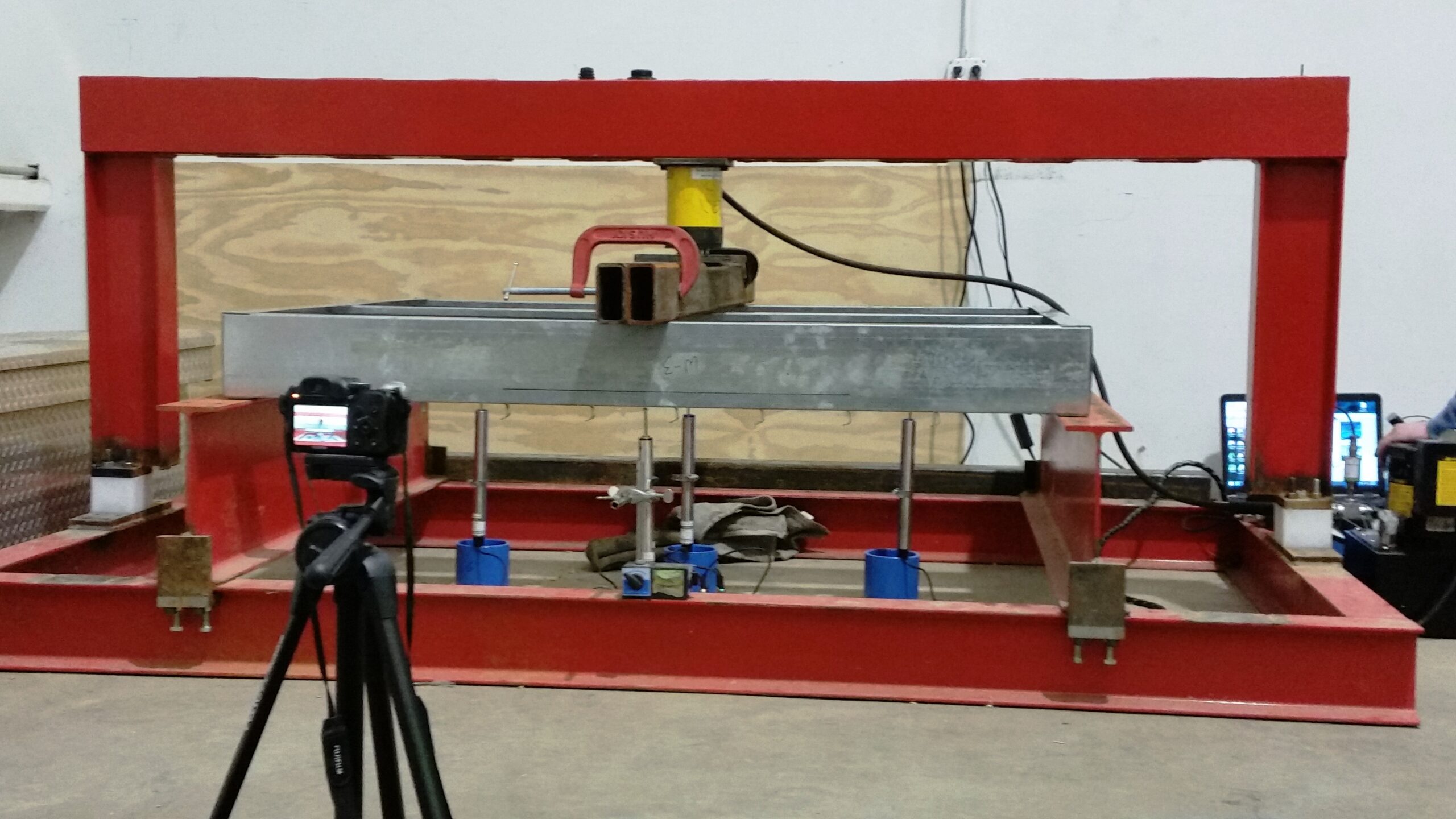

- Flexural Strength

- Freeze-Thaw

- Gel Time

- Heat Deflection

- Initial Cure

- Initial Viscosity

- Polymer Concrete Compress Strength

- Polymer Concrete Flex Strength

- Polymer Concrete Mod. of Elasticity Compress

- Polymer Concrete Shrinkage

- Polymer Concrete Thermal Compatibility

- Pot Life

- Shore HardnessShrinkage

- Tack Free Time

- Tensile Strength + Elongation

- Temp of Gelation

- Viscosity

- Weight Per Gallon

- Epoxy Test Samples

- Compressive Strength

- Absorption

- Splitting Tensile

- Flexural Strength

- Modulus of Elasticity

- ACI Mix Designs

- Concrete mix-design development

- Admixture Certification

- Length Change

- Yield Tests and Unit Weights

- Pozzolanic Activity

- Freeze Thaw

- Creep & Shrinkage

- Testing Fiber Reinforced Concrete

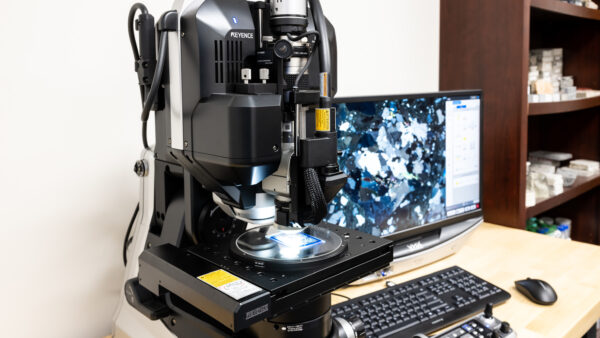

- Petrography and forensic analysis of concrete, aggregate and cementitious materials

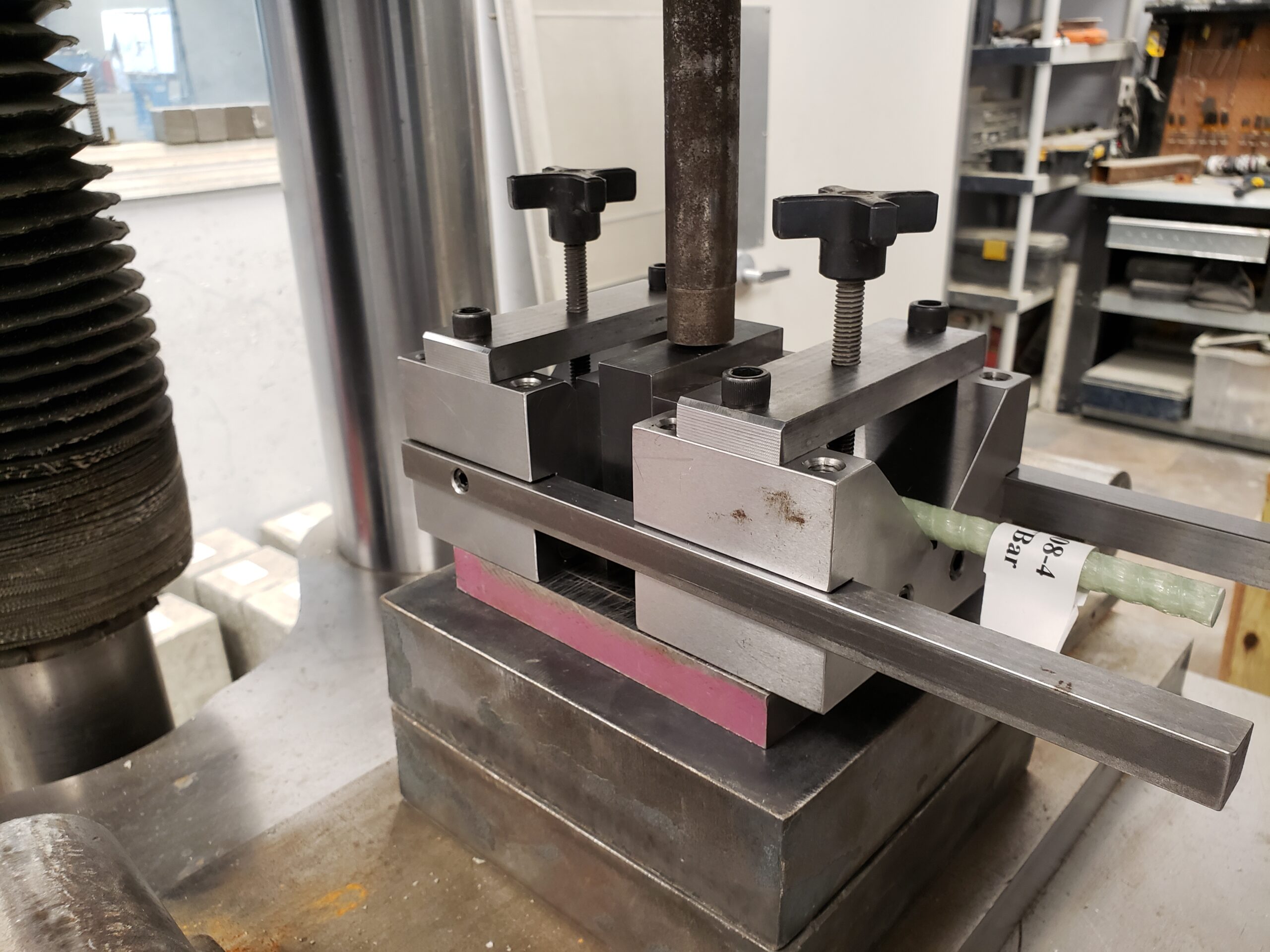

- Physical testing of construction materials, concrete, shotcrete, masonry, wood and steel.

- ASTM C114 Chemical Analysis

- ASTM C150 Physical Analysis

- Compressive & Tensile Strength

- Specific Gravity

- Air Permeability

- Autoclave Expansion

- Time of Setting & Gillmore & Vicat Needles

- Air Content

- Normal Consistency

- False Set

- Compressive Strength

- Absorption

- Prism

- Linear Shrinkage

- Efflorescence

- Fire Rating

- Mortar Design

- Cement and Mortar

- Freeze Thaw

- Chemical/Physical Analysis

- High Strength Bolt Testing

- Anchor Testing

- Elongation

- Modulus of Elasticity

- Tensile Strength

- Freeze/Thaw Testing

- Accelerated Aging Testing

- Modules of Rupture

- Absorption/Bulk Specific Gravity

- Compressive Strength

- Flexural Strength

- Abrasion Resistance

- Full Panel Testing

- Young’s Modulus of Elasticity

- Stone/Anchor System Testing

- Skid Resistance

- Slip Resistance

- Water and Air Infiltration Testing

- Customized Services Are Available Upon Request

SGS TEC Services provides petrographic analysis of aggregate, concrete and cementitious-based products and materials to aid in failure analysis investigations and quality control testing of building materials. This analytical tool can determine the following concrete, mortar and other cementitious products characteristics:

- Estimation of water-cement ratio

- Cause of surface defects

- General quality and condition

- Depth of carbonation

- Identification and volumetric estimation of pozzolanic materials

- Identification of deleterious materials and reactions

- Alkali-silica reactivity

- Chemical and physical sulfate attack

- Degree of carbonation and other environmental effects

- Segregation of Materials

- Aggregate quality

- Maximum aggregate size and gradation

- Entrapped and entrained air contents